0My Cart

0My Cart

Considering purchasing your first micrometer for manufacturing applications but feeling overwhelmed by the options? With several types of micrometers available, each suited to specific measurement needs, selecting the right one can be confusing. This guide will provide an overview of the basics of micrometer use and the key types you are likely to encounter as a beginner. You will learn how to read micrometer measurements, understand the importance of calibration, and identify applications where different micrometer types excel. Equipped with this knowledge, you can make an informed choice when investing in your first micrometer optimised for your needs. Whether you are measuring small machined parts or looking to quantify the thickness of materials, this guide will give you the micrometer literacy required as a starting point.

What is a micrometer?

A micrometer is a precision measuring instrument used to obtain accurate measurements. It consists of an anvil and spindle that move apart or together with a very precise screw mechanism. The anvil remains fixed while the spindle moves towards or away from it.

What is the micrometer’s SI unit?

Did you know, the standard unit of measurement of the micrometer is the micron and denoted by the symbol μm. Micrometers are part of the metric system of units and 1 micron is one millionth of a metre or equivalent to 0.001 millimetres!

Measuring ranges

Due to the fine accuracy, standard micrometers have a limited measuring range from 0 to 25mm and this range can increase in 25mm step (eg.25-50mm,50-75mm,75-100mm) up to even 1000mm for larger micrometers. For resolution, micrometers measure down to 0.001mm or 1 micron. For info, there is a special Mitutoyo micrometer with a higher resolution of 0.1 micron! However it is more expensive and usually not required by most applications. Therefore consider your specific application and needs to choose the appropriate micrometer range. For most precision engineering and manufacturing applications, a standard range from 0 to 25mm is suitable.

Types of micrometer

There are various types of micrometers available for specific measurement needs. The most common types are:

External micrometer

These are employed to measure the outer dimensions of objects. They have two anvils – one fixed and one movable. The most common type is the caliper micrometer. It has a C-shaped frame with the fixed anvil at one end of the frame and the movable anvil attached to a threaded spindle. Certain micrometers such as the 104 series allow the changing of the anvil to cater for a wider measuring range.

Internal micrometer

Internal micrometers come in 2 types caliper type and tubular type. The caliper type have two anvils that face each other while the more popular tubular type such as the 137 series use extension rods. Both are used to measure internal dimensions like diameters of holes. They come in different sizes to suit different measurement ranges. Tubular type are more popular as they come in sets that can extend to a larger distance whereas the caliper type is more suited for smaller hole measurements. Both provide more accurate measurements than vernier calipers.

Depth micrometers

Depth micrometers have a probe to measure depths and steps. They have a spindle that moves a probe vertically to contact the bottom of blind holes, recesses and steps. The depth micrometer reading gives the distance between the end of the probe and the base.

Screw Thread micrometers

Screw thread micrometers have vee-shaped anvils to measure the pitch diameter of screw threads. The vee-shaped anvils fit into the screw thread groove. As the anvils are moved together, the micrometer reading gives the pitch diameter measurement.

Tube Micrometers

Tube micrometers have a pair of anvils that expand to contact the inner and outer walls of tubes and pipes. They provide a quick and accurate measurement of the wall thickness. The tube micrometer has a built-in ratchet stop to lock the anvils in position.

In summary, there are many types of specialised micrometers available to suit different measurement needs. Selecting the right micrometer will allow you to perform accurate measurements for your specific application.

How to use a micrometer?

To obtain an accurate reading using a micrometer, it is important to understand how to properly operate the device. The micrometer consists of an anvil, sleeve, thimble, ratchet stop, and lock nut. Users place the object being measured between the anvil and sleeve.

Zeroing the micrometer

Prior to measuring, the micrometer should be “zeroed”. Loosen the lock nut and turn the thimble until the anvil and sleeve are in contact. Then tighten the lock nut to hold this setting. The reading should now be 0.000 mm. If not, adjust the sleeve scale and vernier scale to align at 0. Your micrometer is now ready to measure accurately.

Measuring

With the micrometer “zeroed”, loosen the lock nut and place the object between the anvil and sleeve. To adjust the spindle, turn the thimble clockwise to decrease the opening size or counterclockwise to increase it. Slide the object into the opening and turn the thimble until it firmly contacts both sides. Apply slight pressure to ensure consistent contact. Tighten the lock nut to maintain the position if required. Be sure to measure at several points along the object to identify any variations in size. Record your measurements for reference. Using a micrometer stand can greatly help the measuring process. To improve measuring speed, Mitutoyo have also released a high speed micrometer, where the spindle can rotate and capture the reading up to 20x faster than standard micrometers!

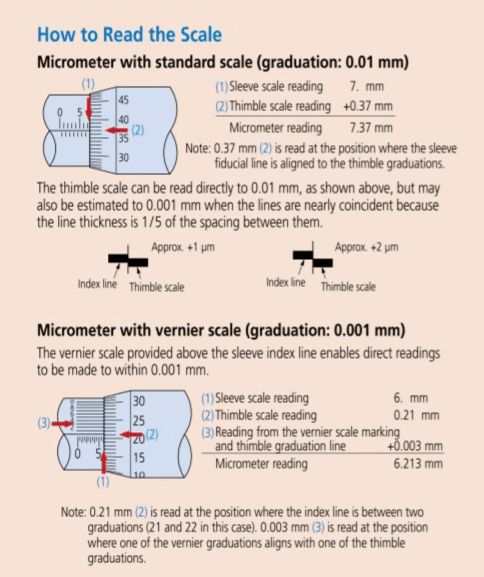

Reading the Scale

For analog micrometers, follow the following steps. Firstly, read off the sleeve scale where the mm or inch markings indicates the largest value. Next, read off the scale on the thimble which indicates the decimal points. You should locate the scale line that most closely aligns with the sleeve scale and take the reading. Note the number of mm or inch markings visible on the sleeve determines the decimal places. Refer to below diagram for an example of a reading. Or you can consider getting a digital micrometer and read directly off the display!

By following these steps carefully, an accurate measurement can be obtained using a micrometer. With regular practise, reading a micrometer will become second nature.

What are the parts of a micrometer to be found?

To understand how to properly operate a micrometer, you must first become familiar with its component parts. The frame, a C-shaped component, holds the anvil and barrel in place. The anvil acts as the stationary jaw and remains fixed in place. The barrel is the moving component that slides along the frame. The thimble is connected to the barrel and used to adjust its position.

The spindle is connected to the thimble and barrel, allowing the barrel to move when the thimble is rotated. The sleeve is marked with measurements to indicate the distance between the anvil and barrel. The lock nut is used to lock the barrel in place once the desired measurement has been set

The ratchet, a mechanism, produces an audible click to help the user determine when the barrel has moved a fixed, known distance as they rotate the thimble. Digital micrometers use an LCD display instead of a sleeve to provide a direct digital readout of the measurement. Some micrometers feature data output connectivity that allows users to store and transmit measurements electronically.

To take a measurement, the thimble is rotated to adjust the barrel until it makes light contact with the workpiece. The measurement is then read from the sleeve or display. The lock nut is tightened to hold the measurement in place if needed. By understanding the parts of a micrometer and how they function together, you will be equipped to effectively use this important measuring instrument. With regular practise, micrometers can become second nature, allowing you to quickly take accurate measurements to suit your needs.

What are the features to consider in choosing a micrometer?

Accuracy and Resolution

The accuracy and resolution of a micrometer are critical factors in selecting the appropriate tool for your application. Higher accuracy and resolution micrometers allow for more precise measurements, down to 0.0001 inches or 0.002 millimetres. For most general purposes, a micrometer with an accuracy of 0.001 inches or 0.01 millimetres is typically sufficient. However, for high-precision machining and metrology applications, higher accuracy may be required.

Output and Data Management

Many digital micrometers come with data output ports that allow you to connect the micrometer to a computer or data collection device. Then, you can automatically record and manage measurements.

Digital micrometers can also make use of Mitutoyo U-Wave. The Mitutoyo Bluetooth® U-WAVE revolutionises the way data is collected by eliminating manual recordings and calculations. With wireless data transmission straight to your smart device, it helps to save time and minimise errors in data transcription.

Some other aspects to consider when choosing a micrometer include the frame size and type, spindle type, and any additional features like a ratchet stop. The micrometer you select depends on the specific measurement range, accuracy, and application needs. Many manufacturers offer a range of micrometers at varying price points to suit most needs. With some research into the available options, you can find a high-quality micrometer well-suited to your particular requirements.

Digital or analogue

You have the choice between digital or analogue micrometers. Digital micrometers display the measurement reading electronically, while you must read analogue micrometers that have a physical vernier scale manually. Digital micrometers are typically easier to read and can automatically capture measurements, but analogue micrometers do not require batteries to operate. For most users, a digital micrometer is more convenient.

Conclusion

In conclusion, micrometers are precision measurement tools capable of high accuracy when used properly. With various types available, micrometers can handle diverse measuring needs from internal dimensions to depth and tube measurements. While requiring a careful, methodical approach, micrometers enable users to obtain detailed data critical across industrial and engineering applications. When paired with data output features, micrometers provide efficient recording and access to measurements. For those new to micrometers, gaining competency starts with understanding the basic components and how to read the measurements. With practise and the right type for the application, micrometers can improve quality control and support precise work. Equipping yourself with a quality micrometer suited to your needs is an investment in producing consistent and meticulous results.

Established in 1988, Regional Tech is a leading supplier for top-notch measurement instruments, including an extensive range of micrometers. As a trusted partner in the manufacturing industry, Regional Tech commits to delivering cutting-edge technology that meets the diverse measuring needs across various sectors, from engineering to industrial applications. Our commitment to quality ensures that professionals and enthusiasts alike can rely on our micrometers to enhance their precision work.

If you’re looking for a groundbreaking variety of precision tools, Find Us!