0My Cart

0My Cart

What is a Force Gauge?

A vital precision instrument used by Singapore’s manufacturing, engineering and quality assurance, it is used to measure force accurately both in tension and compression. It functions by having the measuring point be subjected to a force, which is then transmitted to a load cell built into the gauge. Afterwards the expansion or contraction of the load cell will be detected and converted into force values!

Coming in either mechanical(analog) or digital types, the traditional mechanical force gauge is gradually being replaced by digital as the go to device for providing more accurate readings. Essential for maintaining Singapore’s high standards of product quality and regulatory compliance, check out below for the pros and cons of each!

Digital vs Mechanical Force Gauge: What’s the Difference?

| Feature | Digital | Mechanical |

| Accuracy | High, with digital precision (+) | Moderate, depends on user as require reading alignment of needle to dial face(-) |

| Data Logging | Able to plot Force-Time or Force Displacement Graph with Software. (+) | Manually note down reading (-) |

| Ease of Reading | Digital display straightforward reading with orientation of display being able to reverse according to usage. GO/NG values can be setup for easy reference (+) | Analog dial, require to read needle on dial face (-) |

| Connectivity | USB, Can directly connect to applicable Force Stand for Force Control (+) | None (-) |

| Cost | Higher initial investment, require periodic charging (-) | Lower upfront cost, does not require charging (+) |

How to Choose the Right Force Gauge:

Measurement Range:

Firstly, choose the force gauge with capacity closest to your expected force values for optimal results. This is because the accuracy is determined by the full scale (f.s) and is usually ±0.2% of the scale. However note that if a force gauge is subjected to a force past its rated capacity, the load cell will overload and you will need to purchase a new gauge!

Resolution and Units:

In addition, the 3 main units for measurement are in newtons (N), kilogram-force (kgf), or pounds-force (lbf). For digital types they can usually be interchanged while for analog usually only 1 unit is indicated. Models can also come with 0.1N, 0.01N or 0.001N sensitivity which is dependent on the load cell. Ensure the resolution satisfies your requirement.

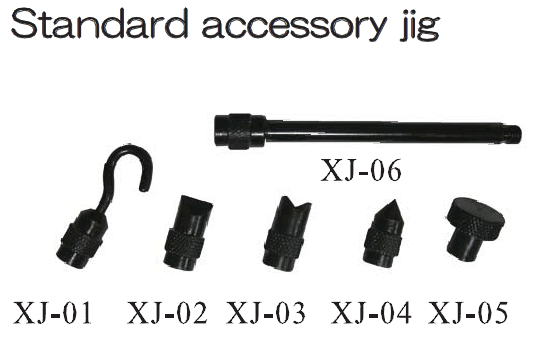

Accessories:

Next, your purchased force gauge will usually come with a list of standard accessories. However, additional hooks, grips, and test stands may be required for your measuring requirement. You can check out our catalog on what is provided and the many available options for attachment.

Data Output Options:

Lastly, USB, RS232 outputs are applicable to Digital types for easy data transfer. However for plotting graphs such as force-time or force-displacement etc, an optional software by manufacturer is required.

Some Key Industries Using Force Gauges:

Electronics & Semiconductors – Test button actuation, connector strength, and component insertion/removal.

Automotive – Component testing (e.g., wire pull-out, latch tension).

Medical Devices – Validation of surgical tools, syringes, and packaging.

Aerospace – Material testing for quality assurance.

Packaging – Seal strength and peel testing of packaging.

Textiles & Consumer Goods – Fabric strength, toy safety testing.

Where to Buy Force Gauges in Singapore:

If you’re based in Singapore and looking to purchase accurate, reliable digital force gauges, consider us Regional Tech! We carry the best and reliable brands from Japan such as Digitech and Imada. Additionally as a local supplier, we offer fast support and local Singlas calibration with ISO/IEC 17025-certified labs!

Maintenance Tips for Long-Lasting Digital Force Gauges:

Make sure to store in a clean, dry environment which avoids exposure to extreme temperatures or humidity.

Additionally, send for calibration periodically to ensure readings are accurate.

Handle carefully! Avoid dropping or impact especially the contact tip.

FAQ

Q: How often should I calibrate my digital force gauge?

A: Generally, calibration period every 12 months is recommended with more or less depending on usage frequency.

Q: Can digital force gauges measure both tension and compression?

A: Yes, digital models and most analog ones will support both modes on the same gauge.

Q:What is “F.S.” for accuracy?

“F.S.” is abbreviation of “Full Scale,” which is the capacity of the force gauge.

Example:

A 100N force gauge offers an accuracy of +/-0.2%F.S.

The error will be: 100N x (+/-0.2%) = +/-0.2N

If you have measured a value of 30N using this, the result is:

30N+/-0.2N = 29.8N or 30.2N

Q:When do I require a test stand?

Choose one if these are important factors for you: direction and the speed of measurement is uniform for highly repeatable measurement results. High capacity measurement, which is hard to measure by hand, can also be done more easily and safely. In addition, if displacement of the gauge relative to the sample is relevant, a test stand with built in linear scale is required.

Conclusion: Why a Force Gauge is Essential?

In conclusion, for industries where knowing how much force is applied is important, this is an indispensable tool. By choosing the right one, it not only improves testing accuracy but also streamlines data collection and enhances productivity.

Ensure the right digital force gauge tailored to your application is selected and contact us today!

Force gauge brands: Digitech, Imada, Aikoh

Keywords: ‘digital force gauge Singapore’, ‘tension and compression gauge’, ‘force-time graph software’, ‘ISO/IEC 17025 calibration Singapore’, ‘IMADA force gauge’, ‘test stand for force gauge

If you’re looking for a groundbreaking variety of precision tools, Find Us!